Morphologies Associated with Processing

▶Introduction◀

고분자는 Extusion 또는 Molding 등에 의해 Film이나 Tubes, Fabrics 등과 같은 여러 가지의 형태로 만들 수 있다.이같이 두께가 두터운 고분자를 원하는 형태의 것으로 가공할 때 나타날 수 있는 모폴로지의 변화와 혼합된 고분자의 모폴로지에 대한 변화를 알아 보자.

(1) Skin/core and related Morphologies

-extruded and injection-molded된 두꺼운 샘플은 cooling하는 동안 내부와 외부의 cooling 속도에 차이가 발생한다. 즉, 내부(nterior, the core)의 cooling속도가 외부(surface, the skin)의 cooling속도 보다 느리다. 따라서 외부와 내부간의 temperature gradient가 존재하기 때문에 외부와 내부, 그리고 중간층(intermediate region)의 모폴로지 또한 차이가 나타날 것이다.

<The center: nondeformed spherulites>

<The surface: highly oriented chains>

<intermediate depth: conical shapes>

ex) polyethylene, polyoxymethylene, isotactic polypropylene

-이와는 다르게 몇몇 polar groups들을 가진 polymer들에서는 Injection molded 나 extruded 된 sample들이 nonoriented noncrystalline skin 과spherulitic core를 가진다.

ex) polyamide 66, poly(butylene terephthalate

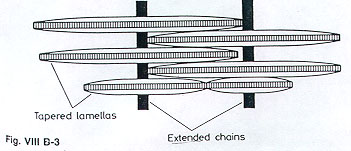

(2) Epitaxial Lamellar Morphology

-capillary rheometer과 같은 작은 orifice를 통해 polyethylene과 같은 flexible chain polymer를 압출 했을 때에는 아래 그림과 같은 압출된 chain에 가느다랗게 interlocking 된 lamella가 epitaxial 한 모폴로지로 나타난다. 이 lamella들은 압출된 방향과 수직으로 배향된다. 반면에 lamella의 결정 stems고 extend된 chain은 압출 방향으로 배향된다.

(3) Blend and Composite Morphologies

① polycarbonate (PC) + Brittle polymer (BP) + Compatibilizer (MBS)

atactic PMMA

atactic polystyrene

styrene/acrylonitrile statistical copolyymer

(SAN 17.5 : acrylonitrile 17.5 %)

(SAN 25 : acrylonitrile 25 %)

(SAN 34 : acrylonitrile 34 %)

상용화제 입자의 분산은 사용한 brittle polymer와 mixing process에 의존적이고, extruder에 의해 수행되어진다.

* BP = atactic PMMA 일 때 MBS는 PMMA상에 모두 다 위치한다. 왜내하면,MBS의 바깥 shell과 PMMA의 화학적 유사성 때문이다.

* BP = atactic polystyrene 일 때 MBS입자는 주로 interface에 위치한다.

* BP = SAN 25 일때 MBS 입자는 interface 와 두 상에 같이 존재한다.

* BP = SAN 17.5 일 때 MBS 입자는 BP상에 존재한다.

* BP = SAN 34 일 때 MBS입자는 PC 상에 존재한다.

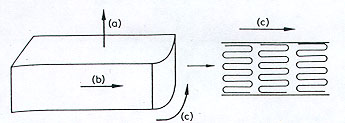

②블렌드한 polymer의 압출된 형태는 구성성분과 가공 조건, 즉 유량이나 온도,구성 성분 의 점도등에 의존적이다.

예) * Liquid crystalline copolymer ( 4-hydroxybenzoate & 6-hydroxynaphthenate) 와 noncrystallizing homopolymer (polycarbonate)의 블렌드는 압출기 내에서 liquid crystalline polymer가 구정 형태나 섬유형 형태를 가진다.

*두 개의 crystallizable polymer, 즉, (poly (ε-caprolactam)와 ethylene/vinyl-acetate copolymer 의 블렌드는 capillary rheometer를 사용해 압출했을 때 구성요소와 가공 온도, rheometer 에서의 시간 등에 의존적이다. 이때 압출된 필라멘트의 바깥쪽 부분의 형태는 불규칙적인 rod형태이고, 내부는 구정과 같은 형태를 가진다.

③두 개의 noncrystallizing polymers( 하나는 높은 Tg를 가지고, 또 다른 하나는 block copolymer 일 때)를 90/10으로 블렌드 하고, 이것을 사출 성형 했을 때, 이들은 homopolyme 제거 후, 아래와 같이 바깥 부분에서는 ball-and-string 구조를 가는 것을 볼 수 있다.

예) Glassy polymer: polycarbonate, Block copolymer: polystyrene/polyacrylonitrile statistical copolymer (rigid portion) + polybutadiene (rubbery part)

(4) Torsional Flow Morphology

조금의 압력의 적용과 torsional flow 조건하에서 polyethylene의 결정은 circular chain 배향을 한다.

(5) Fiber Banding

섬유 방향에 수직 방향으로 나타나는 0.5 - 10㎛ 넓이의 주기적인 band 는 shearing이나 low field의 조건하에서 lyotropic이나 thermotropic liquid crystalline mesophases에서 얻은 샘플에서 나타난다. 이 구조는 main- chain mesogens인 polymer에서 주로 관찰된다. Bands는 shear 방향을 따라 분자 배향의 주기적인 변동을 나타난다.

* polydiacetylene의 Nematic lyotropic mesophase 에서의 Band 형: Herringbond arrangement of lamellas (solvent 제거시)

* athrmotropic liquid crystalline polyester의 결정화 중 shearing 했을 경우: a zig-zag 형 배열의fibril들이 나타난다.