|

Single Lamellas

Single lamellas (platelets) can be formed by isothermal crystallization from a quiescent supercooled melt or solution of a large variety of polymers with a wide range of chain flexibility.

- diamond - hexagonal - pyramidal - square - lathe shapes

In the crystalline part of a lamellar platelet, the polymer chains are usually oriented perpendicular, or nearly perpendicular, to the platelet faces and parallel to the edge structures.

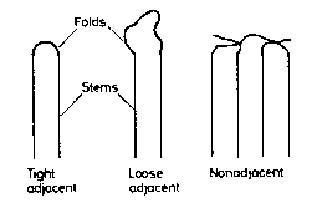

Fig. 3. Folds proposed in single lamellas from flexible chain polymers.

One very important parameter determining the crystal stem length is the degree of supercooling, (degree of supercooling : Tm-Tc, where Tm is the equilibrium melting point and Tc is the crystallization temperature)

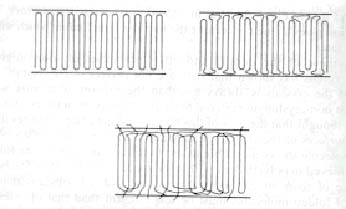

Fig. 4. Schematic illustrations of the different types of folding suggested for polymer single crystals. (a) Adjacent re-entry with sharp folds. (b) Adjacent re-entry with loose folds. (c) Random re-entry or switch-board model.

- high pressure - small degrees of supercooling - long crystallization time

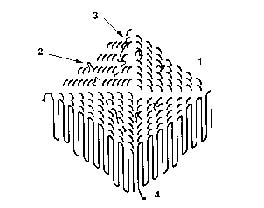

Fig. 5. Polymer single lamella. region 1 - tight adjacent re-entrant region 2 - loose adjacent re-entrant region 3 - nonadjacent re-entrant region 4 - short protruding chain ends

Thickness : 5-20 nm (from solution and the melt at 1 atm) Lateral dimensions : 1000-20000nm Lamellar crystals up to 2 um in thickness and with areas of up to 1 cm2 have been prepared during the polymerization of some polydiacetylene materials.

Fig. 6. Transmission electron micrograph of poly(p-phenylene sulfide) lamellas grown form 0.005% ¥á-chloronaphthalene solution by cooling to 150¡É. ( spear-like shape )

Fig. 7. Electron micrograph of a polyethylene crystal grown from CCl4 at 80 ¡É showing a large growth spiral. The micrograph was obtained by replication and the replica has been shadowed with a heavy metal.

|