|

Spherulites

An aggregation of crystallites as a spherical cluster, consisting of fibrillar crystalline lamellae (the fibril) radiating from the centre of the spherulite, or arising as branches.

1) From a single (heterogeneous) nucleus, 2) From a group of lamellas similar to that in a hedrite, or 3) From a quadrite, a crosshatched lamellar array.

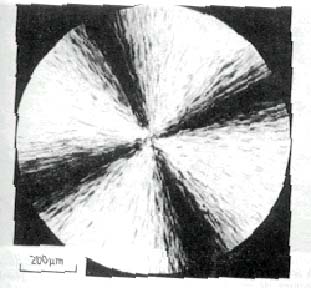

Fig. 12. A single spherulite growing in isotactic polystyrene. Optical micrograph taken in polarized light.

After sufficient supercooling of a relatively concentrated solution or of a melt, spherulites can be grown at constant or slowly decreasing temperature.

Fig. 13. A schematic representation of the growing steps of a single spherulite.

- branching diminishes - the primary lamellas increase in average thickness - additional lamellas fill in the spherulite structures at a later time

spherulites with lamella of greater thickness and length than those obtained at 1 atm.

Regime 1 : - at low degrees of supercooling (high crystallization temperatures) - nucleation events are rare - crystal growth is the main process

Regime 2 : - at lower crystallization temperatures (higher degrees of supercooling) - nucleation is competitive with crystal growth

Regime 3 : - at still higher degrees of supercooling - nucleation occurs at a greater frequency than crystal growth - nucleation is the dominant process

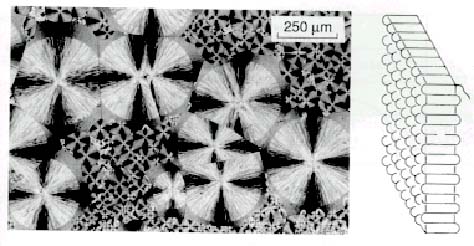

Fig. 14. Crystal structure of polyethylene. Layers similar to that shown in the diagram are edge-on in the photo, being arranged in a radiating pattern to form the prominent crystalline features called spherulites.

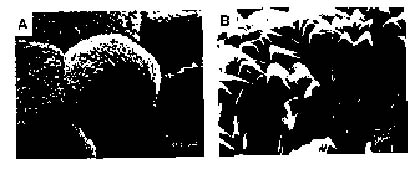

Fig. 15. Scanning electron micrographs of a fracture surface (liquid N2) of isotatic polypropylene crystallized isothermally from the melt in a glass tube at 110¡É for 5 hr after cooling from 200¡É : A. spherulites, B. spherulite surface.

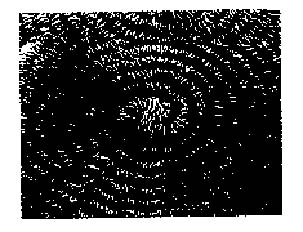

Fig. 16. Scanning electron micrograph of the center of a polyethylene spherulite ion etched at 500 V(ac), 3 ma for 1hr in air.

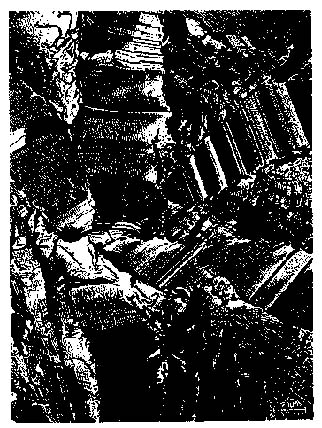

Fig. 17. Transmission electron micrograph of a fracture surface replica of an extruded chain polyethylene spherulite crystallized at 215-225 ¡É and 4.8 kb for 10-20 hr and cooled to room temperature under pressure.

|