|

Defects

Crystalline polymers contain crystalline and amorphous regions and probably also areas which are partially disordered.

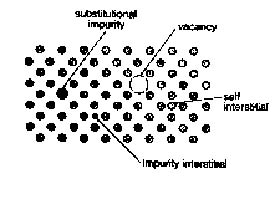

Some types of point defects are illustrated in Figure 22.

Fig. 22. Four types of point defect in a crystalline solid. 1. A substitutional impurity occupies a normal lattice site but is an atom of a different element than the bulk material. 2. A vacancy is the absence of an atom at a normally occupied lattice site. 3. An interstitial is an atom occupying a position between normal lattice sites. (self interstitial that is of the same type as the bulk material, impurity interstitial that is of another kind)

The presence of point defects such as vacancies or interstitial atoms or ions is well-established in atomic and ionic crystals. The situation is somewhat different in macromolecular crystals where the types of point defects are restricted by the long-chain nature of the polymer molecules.

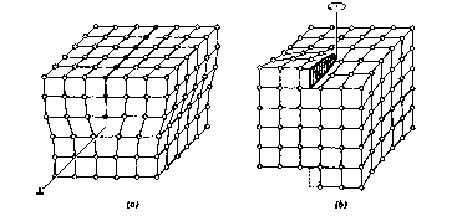

Line defects are called dislocations and are the edges of surfaces where there is a relative displacement of lattice plains.

Fig. 23. The two basic types of dislocations: (a) edge dislocation, and (b) screw dislocation. To create an edge dislocation, an extra row of repeat units must be introduced into part of the lattice; to generate a screw disclocation, a slip of part of the lattice occurs.

(a) There is a high degree of anisotropy in the bonding in polymer crystals. The covalent bonding in the chain direction is very much stronger than the relatively weak transverse secondary bonding. (b) Polymer molecules strongly resist molecular fracture and so dislocations which tend to do this are not favoured. (c) The crystal morphology can also affect the stability and motion of the dislocations. The occurrence of chain folding and the fact that polymer crystals are often relatively thin may affect matters.

The existance of a screw dislocation in polymer lamellas with a size of about 10nm is readly observed due to the formation of spiral growths. Spiral growths are frequently found when crystallization is carried out nonisothermally or at high degree of supercooling. -< polyethylene crystal showing a large growth spiral >-

|